MATERIAL

Made of high-quality galvanized steel plate asstandard, it is sturdy,durable,and aestheti-cally pleasing.

Stainless steel material can also be customizedaccording to user needs.

Products

Contact Us

Add:Xitun East Road, Nanchentun Town, Yunhe District, Cangzhou City, Hebei Province, China

Contact:Manager Wang

WhatsApp:lyh520wpj

Facebook:lyh520wpj@gmail.com

Mobile:+86-18713706961

E-mail:info@jinghangelevator.com

Cangzhou Jinghang Machinery Equipment Co., Ltd. is committed to the design, research and development, production, sales, installation, and after-sales service of conveying equipment. We have professional talents who have been engaged in production, processing, and mechanical equipment manufacturing for many years.

Key words:

Classification:

Description

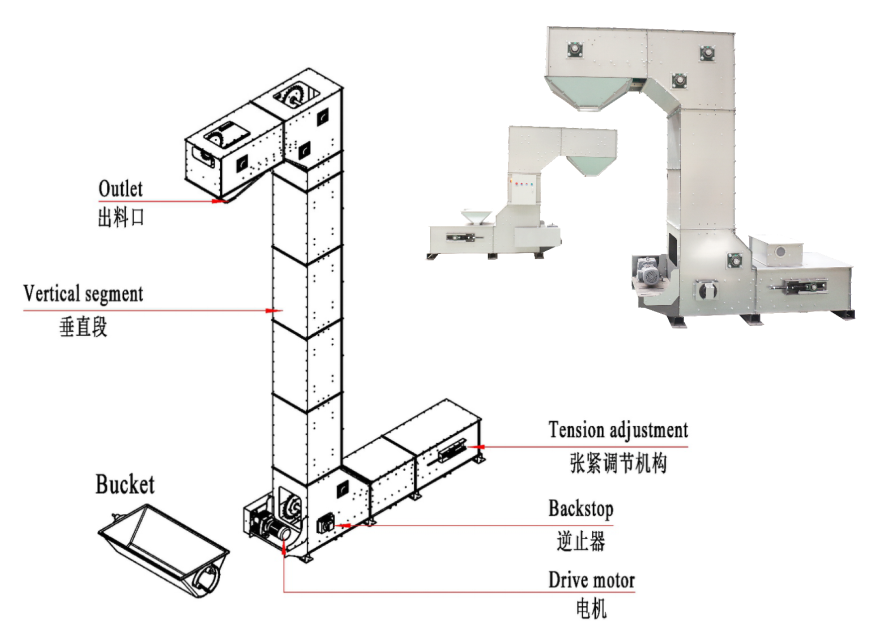

5TS-Series Drive Bucket Elevator

The drive type bucket elevator is a conveyor that transports materials through bucket suspended on chain inside a closed barrel. It can achieve horizontal, vertical, and horizontal combined conveying, and can feed at single or multiple points. Single or multiple point discharge can be completed through the unloading device, and it is fully enclosed without leakage.

Suitable for conveying various powdered and granular materials. The combination form of this machine is flexible, with extremely low material damage rate, suitable for various work scenarios that require gentle handling of materials.

Product Features.

● No material breakage or damage during the transportation process.

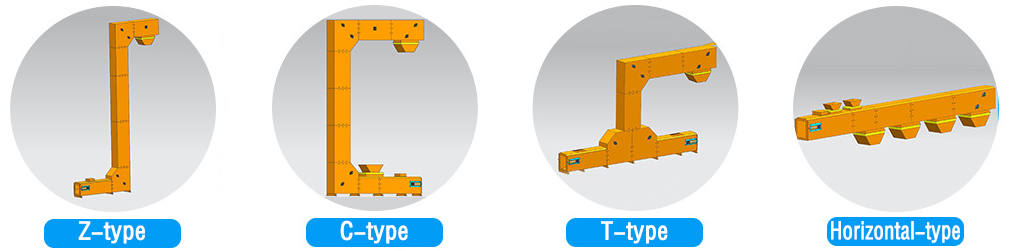

● It can be designed as Z type, C type, T type according to customer needs.

● Single or multi-point feeding, single or multi-point unloading.

● Leak free compact buckets.

● Standard high-quality nickel plated chain, corrosion-resistant and low wear.

● Modular design, horizontal segment length and vertical segment height can be customized according to user requirements.

● Equipped with a torque limiter, in case of unexpected malfunctions during operation, the torque limiter will protect the machine from damage and automatically shut down.

● Compact structure and small footprint.

● Energy saving, environmentally friendly, easy to install and maintain.

Working Principle.

When elevator is working, the reduction motor drives two chain wheels to move synchronously through bearings, thereby causing the two chains to move synchronously on the track.

The material falls into the horizontal forward buckets through the feeding hopper. As the material slides into the buckets instead of being forcibly scraped, it will not cause the material to break.

The synchronous movement of the two chains causes the buckets between them to continuously move on its track. The transition between horizontal and vertical conveying is accomplished by two sets of pulley units located at the upper and lower corners;

The material is transported to the discharge port or the middle discharge port, and the special shaped guide rail of the discharge port raises the guide pin of the bucket, causing the bucket to tilt and empty the material.

Technical Parameter.

Model | Capacity | Height | Power | ||

Full-bucket | 70%-bucket | Wheat seed | |||

5TD-06 | 6 m3/h | 4.2 m3/h | 3.1~3.5 t/h | 2~15 m | 0.75kW |

5TS-15 | 15 m3/h | 10.5 m3/h | 7.5~8.5 t/h | 2~25 m | 0.75~1.5kW |

5TS-20 | 20 m3/h | 14 m3/h | 10.5~11.2 t/h | 2~25 m | 0.75~1.5kW |

5TS-30 | 30 m3/h | 21 m3/h | 15.5~16.8 t/h | 2~25 m | 2.2~3kW |

5TS-40 | 40 m3/h | 28 m3/h | 21~22.4 t/h | 2~25 m | 2.2~3kW |

Noted: The wheat seed lifting capacity is converted based on a bulk density of 750~800 Kg/m3.

Main Structure.

Application.

The drive bucket elevator can be widely used for various materials that require gentle processing. Suitable for Z-type, C-type, T-type feeding, multi-point feeding, multi-point unloading and other occasions. At present, it is mainly used for feeding packaging scales, color sorter, three-dimensional cycle loading and unloading of automated production lines, and multi-point feeding of fully automatic weighing and batching systems.

This equipment is suitable for the following automated production industries: seed processing industry, pet food industry, puffed food industry, feed industry, candy industry, dried and fresh fruit industry, food industry, grains fine-processing industry, chemical and pharmaceutical industry, hardware and electrical materials industry, etc.

Project Case.

Model Selection Notice.

According to your material type, processing capacity per-hour, height (distance from discharge outlet to ground), and horizontal length of upper and lower sections, you can choose the appropriate machine model.

Cangzhou Jinghang Machinery Equipment Co., Ltd. is committed to the design, research and development, production, sales, installation, and after-sales service of conveying equipment. We have professional talents who have been engaged in production, processing, and mechanical equipment manufacturing for many years. The company has advanced equipment such as laser cutting machines, CNC bending machines, CNC lathes, and a complete and scientific quality management system.

Starting from customer needs, tailor-made to meet the personalized needs of many enterprises. The products are widely used in various industries such as grain, environmental protection, metallurgy, medicine, military industry, electronics, food, chemical industry, pet food, etc.

Excellent products, comprehensive services, and exquisite craftsmanship have won unanimous praise in the market. Warmly welcome friends from all walks of life to visit and guide us, and negotiate business.

Plant Equipment

Related Products

Consultation